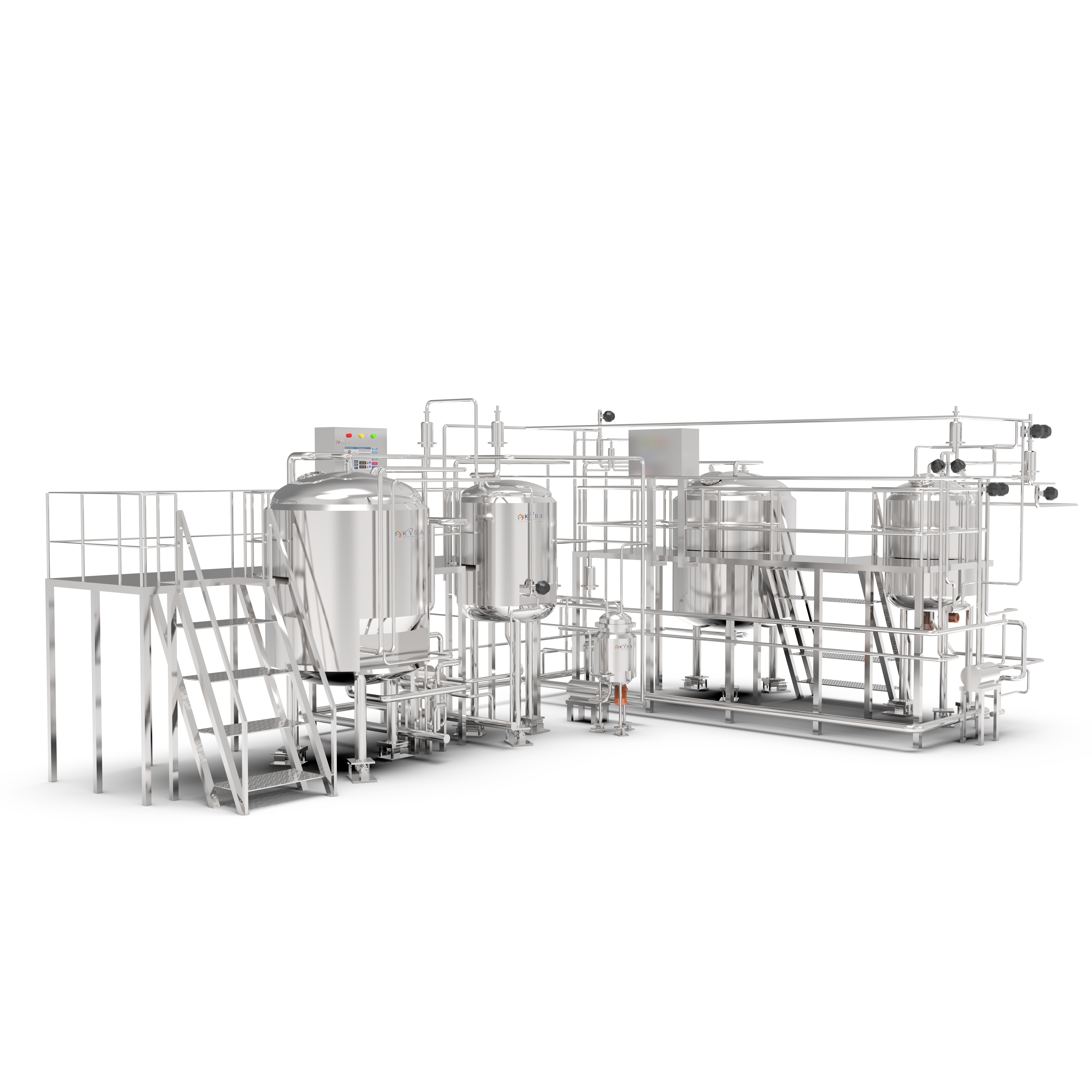

Liquid Oral Processing Plant Specification

Technical Specification

- Capacity - 500 - 10000 Ltrs

Application

- MOC - SS304/ SS316/ SS316L

- Vessel design as per ASME guidelines

- Pipe fitting are of seamless quality, internally electro polished with tri-clover ended joints.

- Liquid Mfg. Plant Consists of followings:

- Sugar Melting Vessel

- Syrup Mfg. Vessel

- Storage Vessel

- Working Platform

- Interconnecting Pipeline

- Control Panel

- Pre filtration - Basket Filter

- Final filtration - Sparkler Filter

- Inline Homogenizer

- Centralized Operating Panel

- Qualification Documents - IQ, DQ, OQ and FAT Protocol

Optional Items/ Accessories

- Weighing Facility (Load Cell)

- PLC based, with touch screen HMI and SCADA packages

- 21 CFR Part 11- Provision and Compliance

- Thermowell and Thermosiphon

- FLP Control Panel

- Utility Pipeline- Manual or Automatic

- Transfer systems for Sugar / Glucose through vacuum system

- Fully Automatic Process Plant with actuated Valve

- Branded/reputed make accessories (VFD, Load Cell, Valves, Pressure Gauge, Diaphragm Valve, Spray Ball, Steam Trap, Sight Glass, wiper, Sensor, and Electrical Components etc.)

NB: Spares items also available like Gasket, Homogenizer, Mechanical Seal, Motor, Valves, and other components etc.